Food and Beverage Industry

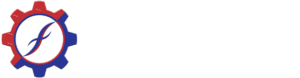

Pasteurizer

Pasteurization is a process in which packaged and non-packaged foods (such as milk and fruit juice) are treated with mild heat, usually to less than 100 °C (212 °F), to eliminate pathogens and extend shelf life.

Engineering Works:

- PLC Programming

- HMI Development

- Start-up and Commissioning

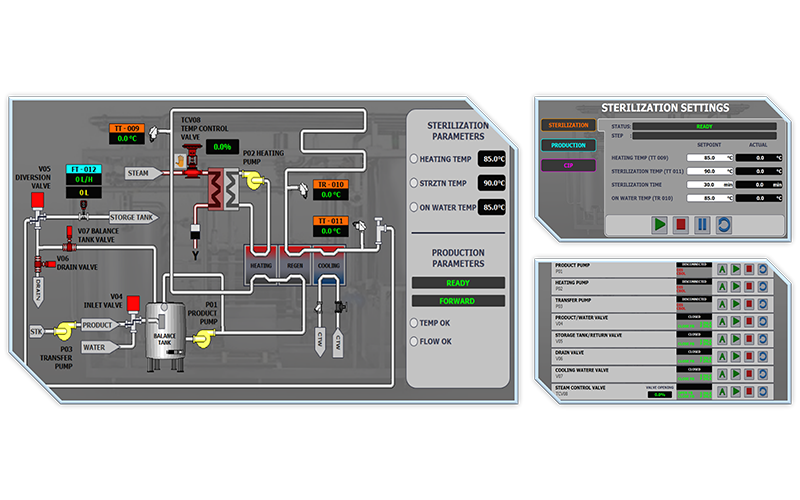

CIP is a highly automated process during which vessels and pipeline systems do not need disassembly for cleaning and sanitizing.

Engineering Works:

- PLC Programming

- HMI Development

- Start-up and Commissioning

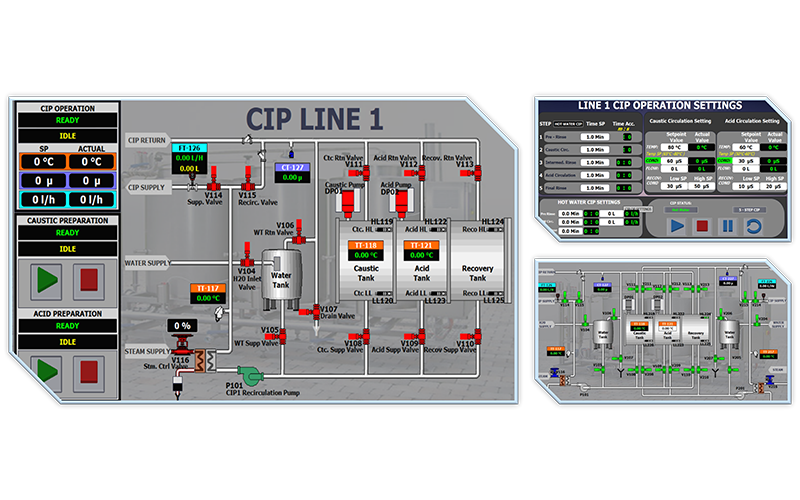

HTST (High Temperature Short Time)

The aseptic process uses the high-temperature–short-time (HTST) method in which foods are heated at a high temperature for a short period of time. The HTST method results in a higher retention of quality characteristics, such as vitamins, odor, flavor, and texture, while achieving the same level of sterility as the traditional canning process in which food is heated at a lower temp

Engineering Works:

- PLC Programming

- HMI Development

- Start-up and Commissioning

Conditioning cylinder is used to heat, open and moisturize the tobacco products to specified exit tobacco temperature and moisture targets, while ensuring sufficient resistance time to achieve 100% kill of all life stages of any insects that may be in the tobacco.

Engineering Works:

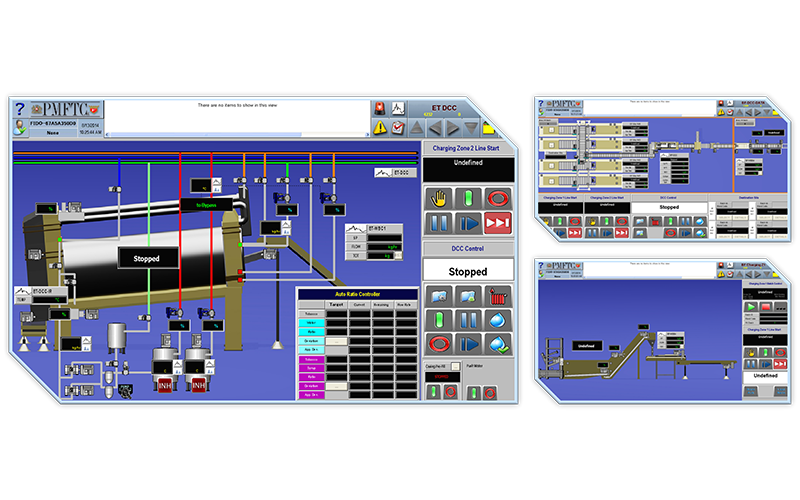

- PLC Programming

- HMI Development

- Start-up and Commissioning